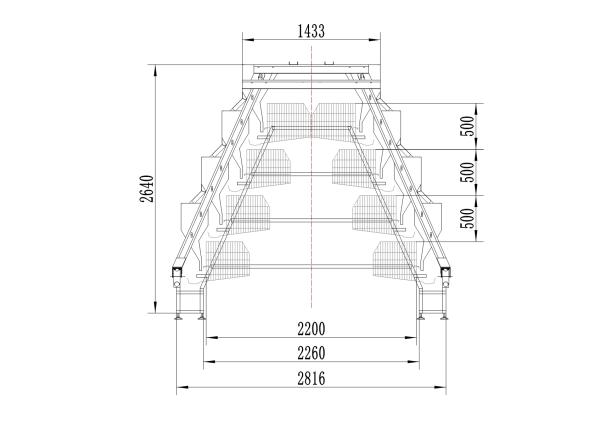

In modern large - and medium - sized egg farms, space utilization is a crucial factor affecting operational efficiency. The H - type egg cage structure stands out as an excellent solution. Let's first understand how its structure differs from traditional flat cages. Traditional flat cages often have a single - layer or simple multi - layer design, which not only occupies a large amount of floor space but also has limited vertical space utilization. In contrast, the H - type layer - stacked design of the H - type egg cage can stack multiple layers vertically, effectively increasing the number of chickens that can be raised per unit area.

According to research data, compared with traditional flat cages, the H - type egg cage can save more than 30% of the floor area. This significant space - saving effect is mainly due to its reasonable vertical layout. By optimizing the distance between layers and the arrangement of cages, the H - type structure can achieve a higher density of chicken raising without sacrificing the living space of the chickens.

For medium - and large - sized egg farms, the ability to expand flexibly according to business development is very important. The modular design of the H - type egg cage provides strong support for this. Each module of the H - type egg cage can be assembled and disassembled independently, which means that farms can increase or decrease the number of cages according to their own needs.

For example, when a farm needs to expand its scale, it only needs to add corresponding modules, and these modules can be quickly integrated into the existing system without major reconstruction of the entire farm. This modular design not only saves time and cost but also ensures the stability of the farm's operation during the expansion process.

The H - type egg cage is usually equipped with an automatic feeding, manure cleaning, and egg collection system. These systems can significantly reduce the dependence on manual labor and improve management efficiency. The automatic feeding system can accurately control the amount and time of feed supply, ensuring that each chicken gets sufficient and balanced nutrition. The automatic manure cleaning system can regularly clean the manure in the cage, maintaining a clean and hygienic living environment for the chickens.

The automatic egg collection system can quickly and gently collect eggs, reducing the damage rate of eggs. According to statistics, the use of these automatic systems can reduce labor costs by more than 40% and increase the management efficiency of the farm by more than 50%.

According to poultry ethology research, the uniformity of lighting and the ventilation path have a significant impact on the egg - laying performance of chickens. The H - type egg cage structure can ensure uniform lighting in the cage through a reasonable design. Uniform lighting can regulate the biological rhythm of chickens, stimulate their egg - laying potential, and improve the egg - laying rate.

In terms of ventilation, the H - type structure can form a scientific ventilation path, which can quickly remove harmful gases such as ammonia and carbon dioxide in the cage and bring in fresh air. This good ventilation environment can effectively reduce the incidence of chicken diseases and improve the health of the chicken flock.

Let's look at the actual application of the H - type egg cage. In a chicken farm in [location], after replacing the traditional flat cages with H - type egg cages, the floor area of the farm was reduced by 35%. At the same time, the labor cost was reduced by 45%, and the egg - laying rate of the chicken flock increased by 15%. The incidence of chicken diseases also decreased significantly, from 12% before the transformation to 5% after the transformation.

These data clearly show that the H - type egg cage can not only improve the space utilization and management efficiency of the farm but also improve the health and egg - laying performance of the chicken flock.

To further enhance the credibility of the H - type egg cage, we can refer to customer testimonials and case videos. Many farm owners who have used the H - type egg cage have given positive feedback. One farm owner said, "Since we installed the H - type egg cage, our farm has become more efficient. The automatic system has saved us a lot of labor, and the egg - laying rate of the chickens has also increased. It is really a great investment."

These real - life examples and customer testimonials can help potential customers better understand the advantages of the H - type egg cage and increase their confidence in choosing this product.

In conclusion, the H - type egg cage structure is a high - efficiency, space - saving, and cost - effective solution for medium - and large - sized egg farms. If you are looking for a way to optimize your farm's space utilization, improve management efficiency, and increase egg - laying rates, the H - type egg cage is definitely worth considering. Click here to learn more about our H - type egg cage products and start your efficient egg - farming journey!