Tanzania's poultry sector has long faced challenges balancing productivity, operational costs, and sustainability. Small-scale farms, in particular, struggle to maintain profitability while adhering to sustainable practices that protect both their business longevity and the environment. Amid these challenges, one Tanzanian poultry farm has successfully transformed its operations — and its prospects — by adopting the cutting-edge A-Type layer chicken battery cage from Zhengzhou Livi Mechanical Manufacturing.

The farm switched to the A-Type chicken battery cages constructed from hot-dip galvanized Q235 steel — a material known for exceptional corrosion resistance and mechanical strength. This ensures the cages withstand Tanzania’s varied climatic conditions with minimal wear, providing a lifespan of 15 to 20 years. Such durability makes this solution a cost-effective long-term investment compared to traditional wooden or uncoated metal alternatives.

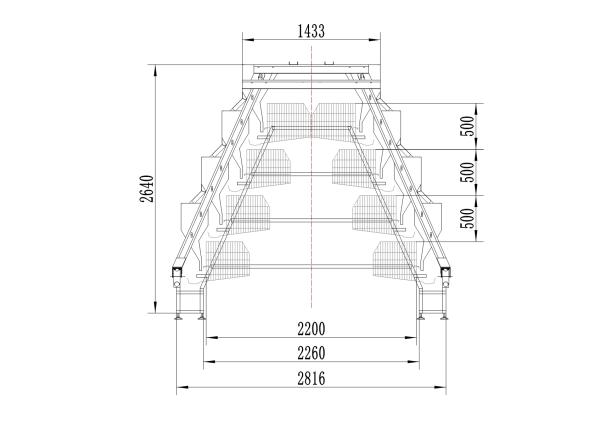

With options ranging from 3 to 5 tiers, the cages offer remarkable flexibility in vertical stacking, enabling farms to optimize their spatial footprint. What's more, the cages can be customized to accommodate different flock sizes as per precise requirements. This adaptability empowers farms to scale operations efficiently without compromise.

Integral to these cages is an automated feeding and waste management system that significantly cuts down manual labor and maintenance costs. Automation ensures consistent feed delivery and hygienic waste removal, creating a healthier environment that promotes higher egg production. The automation also reduces human error, enhancing overall productivity.

The farm observed egg production rates exceeding 90% during peak laying periods after implementing the A-Type cages, a significant improvement compared to previous yields. This boost is attributable to the optimized environment and food availability provided by the automated system and ergonomic cage design.

Beyond Tanzania, this product has garnered acclaim in African markets including Nigeria, Kenya, and South Africa, where poultry farmers report similar productivity and sustainability benefits. For instance, Nigerian poultry farmers managing up to 20,000 layers have successfully adopted the cages, witnessing enhanced flock health and operational efficiency.

This growing international adoption affirms the cage’s reliability and adaptability across different operational scales and geographic conditions.

By investing in the innovative A-Type layer chicken battery cages, Tanzanian poultry farms can confidently align with sustainable development goals—maximizing productivity while minimizing resource consumption and environmental footprint. The combination of durable materials, design versatility, and automation delivers a practical and future-proof solution that drives profitability and ecological responsibility.

Ready to Transform Your Poultry Farm?

Discover how Zhengzhou Livi Mechanical Manufacturing’s A-Type layer chicken battery cages can enhance sustainability and productivity on your farm. Contact our expert team today for tailored solutions and quotations designed to meet your unique needs. Join the growing community of successful poultry farmers harnessing innovation for a thriving future!

Request a Free Consultation