In the competitive landscape of poultry farming, quality enhancement and operational efficiency are paramount for sustaining profitability and market reputation. A leading layer farm in Ghana recently addressed these challenges head-on by integrating state-of-the-art technology into their production system—specifically, the advanced A-type layer battery cage supplied by Zhengzhou Livi Machinery Manufacturing.

Ghanaian poultry farmers have long grappled with unpredictable egg yields and inconsistent egg quality, often resulting from suboptimal housing conditions and manual labor-intensive processes. These challenges have historically capped production efficiency during peak laying periods to under 85% at best. Additionally, concerns regarding durability and hygiene in poultry housing materials have affected biosecurity and maintenance costs.

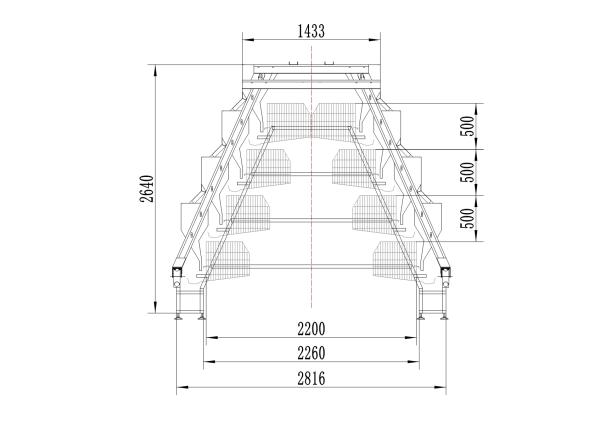

The farm’s decision to adopt the high-efficiency A-type layer battery cage system brought transformational benefits. Crafted from premium hot-dip galvanized Q235 steel, this cage system ensures superior rust resistance and structural strength, critical for the humid tropical climate of West Africa. Customers can choose configurations ranging from 3 to 5 tiers, with options for customized design parameters to suit specific operational workflows.

Key automated features include integrated feed and water lines, manure collection mechanisms, and controlled ventilation pathways. Such automation minimizes labor input while enhancing bird welfare and environmental hygiene, directly correlating with health improvements and egg production consistency.

Since integrating the Livi cage system, the Ghanaian farm reported a remarkable surge in egg production rates during peak laying periods, achieving a consistent over 90% peak egg-laying rate. This 5+ percentage point improvement over prior benchmarks translated to substantial volume gains without proportional increases in resource consumption.

Moreover, egg quality indicators such as shell strength and uniformity improved significantly, meeting stricter export and local market standards. Independent quality assessments confirmed a 10% reduction in egg breakage and defects, bolstering the farm’s reputation and customer satisfaction.

"The automated cage system radically transformed our operation. Not only did egg production increase, but labor requirements dropped by 20%. The durability and ease of maintenance have truly made this a wise investment." – Farm Manager, Ghana

The longevity conferred by hot-dip galvanized Q235 steel significantly reduces lifecycle costs amidst challenging environmental conditions. Modular tiering supports scalable expansion aligned with market demand. Automated operation curtails labor shortages and operational errors, making the system highly suitable for intensive poultry farms aiming to penetrate competitive domestic and international markets.

By integrating this advanced cage technology, the Ghanaian farm is poised to maintain a leadership position by offering high-quality eggs consistently and sustainably, providing a replicable model for African poultry producers.

The incorporation of Zhengzhou Livi’s A-type layer battery cages represents a pivotal advancement in poultry farm management within Ghana. The tangible improvements in egg yield, enhanced egg quality, labor efficiency, and farm sustainability showcase the product’s critical role in elevating competitive advantage.

Ready to boost your poultry farm’s production and profitability?

Contact Zhengzhou Livi Machinery now for customized solutions tailored to your operation needs.