In the modern large - scale poultry farming industry, the traditional manual egg - collection method has long been unable to meet the needs of efficient management. This article will comprehensively guide you through the practical implementation of automating egg - collection systems in large farms, from installation assessment to daily maintenance.

Manual egg - collection in large farms is labor - intensive and time - consuming. On average, a worker can collect about 1000 - 1500 eggs per hour, which is far from meeting the high - output requirements of large farms. Moreover, manual handling can easily lead to egg damage, with a damage rate of approximately 2% - 3%. As the industry develops, automating egg - collection has become an inevitable trend to improve efficiency and egg quality.

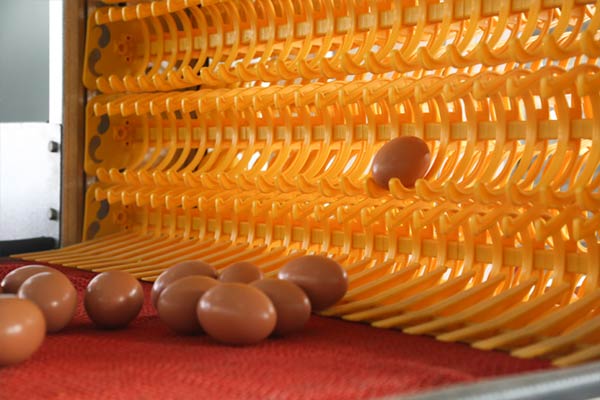

The drum - type egg - collection system uses rotating drums to gently roll eggs out of the cages. Its advantage lies in its relatively simple structure and low cost. In a farm with 10,000 laying hens, this system can collect eggs at a speed of about 2000 - 2500 eggs per hour. However, its drawback is that it may have a relatively high egg - breakage rate, around 1% - 1.5%.

The conveyor belt system transports eggs through a moving belt. It can be integrated with H - type chicken cages, which is more suitable for large - scale farms. In the same 10,000 - hen farm, it can collect eggs at a speed of 3000 - 3500 eggs per hour, and the egg - breakage rate is relatively low, about 0.5% - 1%.

Both systems are designed to work in synergy with H - type chicken cages. The unique structure of H - type cages allows eggs to roll or be transported smoothly onto the egg - collection devices, reducing the risk of egg breakage during collection.

Let's compare the two systems through real - case data:

| System Type | Egg - Collection Efficiency (eggs/hour) | Failure Rate | Cleaning Difficulty |

|---|---|---|---|

| Drum - type | 2000 - 2500 | About 5% - 7% per year | Relatively high, complex drum structure |

| Conveyor Belt | 3000 - 3500 | About 2% - 3% per year | Relatively low, simple belt structure |

Before installation, it is necessary to measure the chicken house size. For example, for a conveyor belt system, a minimum width of 2 - 2.5 meters is required on both sides of the H - type cages to ensure smooth operation. Also, sufficient height should be reserved for equipment installation and maintenance.

The drum - type system generally requires a power of about 1 - 1.5 kilowatts, while the conveyor belt system may need 2 - 3 kilowatts. The farm's power supply system needs to be evaluated to ensure stable power supply.

Operators should receive at least 2 - 3 days of training, including equipment operation, simple troubleshooting, and safety knowledge. This can reduce the probability of human - induced failures.

Common problems include belt slippage in the conveyor belt system and drum jamming in the drum - type system. Regular cleaning (at least once a week), lubrication of moving parts (once every two weeks), and inspection of electrical components (once a month) can effectively extend the service life of the equipment and improve its operational reliability.

Are you interested in automating your farm's egg - collection system? Zhengzhou Livi Machinery provides professional solutions. Click here to learn more!