Traditional poultry farming in Zambia has long grappled with challenges such as labor-intensive management, suboptimal egg yields, and hygiene concerns. Manual feeding, egg collection, and waste removal not only consume excessive human resources but also limit scalability and farm productivity. Recognizing these constraints, many forward-thinking poultry operators are embracing intelligent solutions to modernize operations and enhance performance.

At the forefront of this transformative wave is Zhengzhou Livi Machinery Manufacturing Co., Ltd., offering the High-Efficiency A-Type Layer Battery Cage — a product designed to meet diverse poultry farming needs while significantly boosting operational efficiency and egg output.

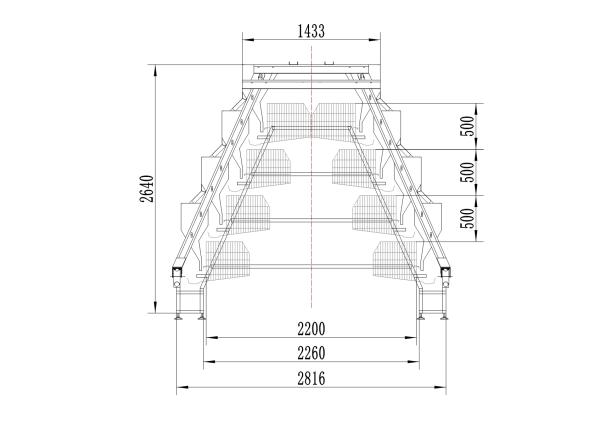

Constructed from premium galvanized steel with robust anti-corrosive coatings, the cage system ensures optimal durability and longevity, even in harsh farm environments. Featuring a multi-tier design, each unit comprises 4 to 6 layers, maximizing vertical space utilization and accommodating up to 120 hens per battery cage section. This compact yet expansive setup drastically increases farm stocking density without compromising animal welfare.

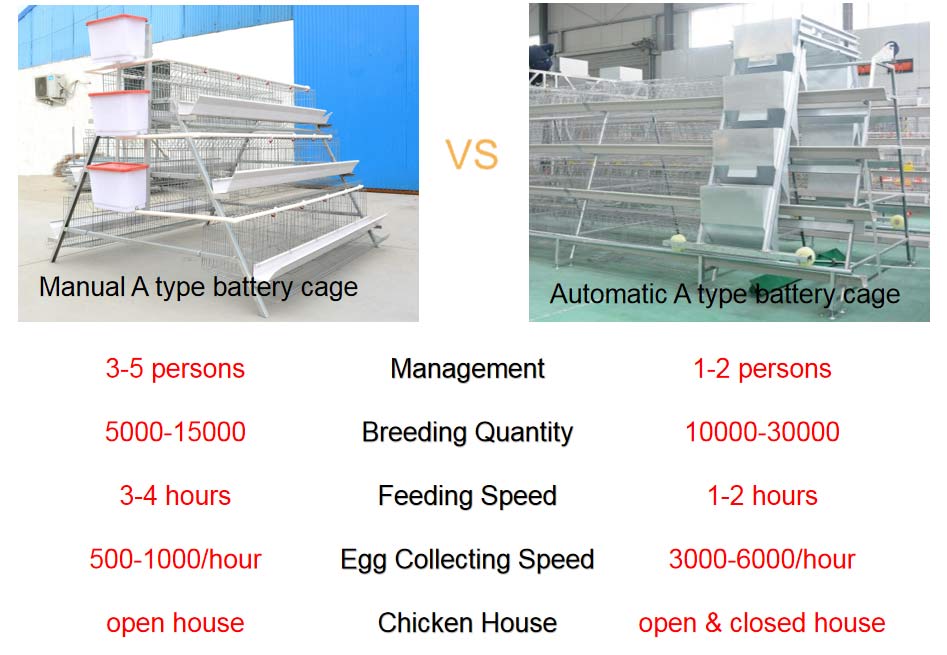

The intelligent system integrates fully automated feeding mechanisms using conveyor belts and programmable timers, ensuring hens receive the right nutrition at optimal intervals, promoting healthier flocks and uniform growth. The design includes an advanced manure removal system that automatically channels waste away from the cages, maintaining hygiene and reducing disease risk.

Most notably, the automated egg collection conveyor gently transports eggs to centralized collection points, minimizing breakage and labor involvement. This automation drastically lowers the risk of contamination and handling damage, resulting in higher quality eggs ready for market.

A leading poultry farm in Zambia recently adopted the High-Efficiency A-Type Layer Battery Cage system, achieving remarkable results within the first year. Post-upgrade data indicates:

| Metric | Before Upgrade | After Upgrade |

|---|---|---|

| Average Egg Production Rate | 68% | 85% |

| Labor Hours per 1000 Birds / Week | 40 hours | 15 hours |

| Manure Management Efficiency | Manual, Time-Consuming | Automated, Hygienic |

This shift not only elevated egg yield by 25% but also cut labor requirements by over 60%, representing substantial cost savings and operational streamlining.

Beyond Zambia, numerous poultry farms in Nigeria, Kenya, and South Africa have reported similarly positive outcomes. For example, a Kenyan operator explained, “Installation of the A-Type Layer Battery Cage brought consistency in production and significantly reduced labor-related challenges, allowing us to scale our business sustainably.”

The widespread adoption across multiple regions underscores the product’s ability to adapt to varying climatic and operational conditions, meeting diverse farmer demands globally.

In an increasingly competitive market, smart poultry farming technologies like the High-Efficiency A-Type Layer Battery Cage offer a clear path to elevated productivity and operational excellence. By automating feeding, cleaning, and egg collection, farms gain enhanced control, lower operational costs, and greater output consistency.

Farmers seeking to modernize operations, boost egg yields, and optimize labor should consider this tested, reliable solution developed by Zhengzhou Livi Machinery Manufacturing Co., Ltd. It delivers a comprehensive upgrade designed to satisfy varied farm scales and configurations.