Traditional poultry farming in Zambia, like in many emerging markets, faces persistent challenges including labor-intensive processes, inconsistent egg production rates, and suboptimal space utilization. These constraints limit profitability and restrict growth potential. Recognizing this, leading farms in Zambia have embraced smart, automated poultry solutions to overcome such hurdles and drive sustained improvements.

At the heart of this transformation is the high-performance A-Type Layer Battery Cage system developed by Zhengzhou Livi Mechanical Manufacturing Co., Ltd. Designed to meet diverse operational needs, these battery cages exhibit superior durability and modular adaptability — revolutionizing how poultry farms manage their flocks with precision and efficiency.

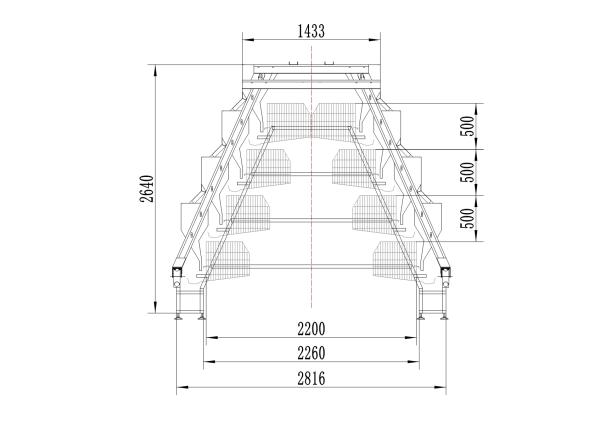

Constructed from high-grade galvanized steel with corrosion-resistant coatings, the A-Type layer battery cages guarantee lasting structural integrity in diverse environmental conditions. Farms can customize the number of tiers and cage dimensions according to flock size, enabling optimized spatial efficiency. A typical setup can house up to 60 layers per cage system, dramatically increasing capacity without expanding farm footprint.

The true smart advantage comes from the automated feeding, watering, and manure removal features seamlessly integrated into the cage design. In Zambia, farms deploying these systems report a reduction in manual labor by over 40%, freeing staff to focus on farm management and quality control activities. Simultaneously, the precise feed delivery minimizes waste by up to 15%, further driving down operational costs.

| Key Metrics | Before Upgrade | After Upgrade |

|---|---|---|

| Average Daily Egg Production | 65% | 82% |

| Labor Hours per 1000 Birds | 30 hours | 18 hours |

| Feed Efficiency | 2.1 kg feed/kg eggs | 1.8 kg feed/kg eggs |

The increase in egg production and feed efficiency, combined with significant labor savings, illustrates the substantial economic impact of the upgrade. Farms in Lusaka and the Copperbelt have independently verified these benefits and continue to vouch for the reliability and ROI of the system.

Beyond Zambia, Zhengzhou Livi Mechanical’s A-Type layer battery cages have earned praise from poultry operations in Kenya, Tanzania, and Ghana. Customers highlight the system’s ability to adapt to local conditions and operational scales, supported by responsive after-sales service and training provided by the company.

These real-world examples reinforce the product’s versatility and tangible value, making it a smart investment for poultry producers aiming to future-proof their farms amid growing industry demands.

Smart poultry farming driven by automation and robust design significantly reduces costs while raising productivity. The A-Type Layer Battery Cage system from Zhengzhou Livi Mechanical stands out as an ideal solution, offering farms customizable, durable, and user-friendly infrastructure that responds flexibly to evolving market conditions.

For poultry producers in Zambia and beyond seeking to enhance operational efficiency and profitability, adopting this smart battery cage system is a proven path. Leveraging the experience of satisfied farms can guide your upgrade journey toward sustainable growth and competitive edge.

Discover how the A-Type Layer Battery Cage system can tailor to your farm’s needs, help you cut costs, and boost egg production efficiency with automated precision.

Contact Us Today for a Customized Solution