For many small-scale poultry farmers, especially in developing countries like Tanzania, maintaining profitability amidst rising costs and inefficiencies remains a persistent challenge. The struggle to reduce operational expenses while boosting egg production capacity often limits sustainable growth. This article explores how innovative equipment like the High-Efficiency A-Type Layer Battery Cage from Zhengzhou Livi Machinery Manufacturing is revolutionizing poultry management by addressing these very challenges.

Small-scale farms in Tanzania typically face difficulties such as expensive feed management, labor-intensive operations, and low egg yield per flock. Limited automation means more manual labor, higher chances of waste, and inconsistent production cycles. Many farms spend upwards of 30% of total expenses on daily maintenance, leading to razor-thin profit margins.

The solution offered by Zhengzhou Livi’s A-Type Layer Chicken Battery Cage directly addresses these pain points. Constructed from premium hot-dip galvanized Q235 steel, the cage boasts exceptional durability with an expected lifespan of 15 to 20 years, well suited to tough farming environments.

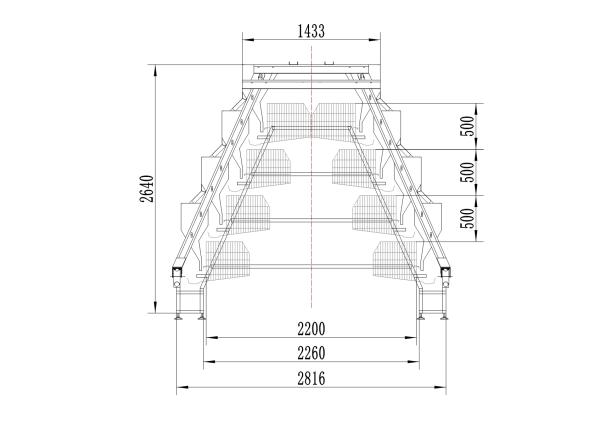

This cage system is available in configurations ranging from 3 to 5 tiers and customizable to accommodate flocks up to 160 chickens, allowing farmers to optimize space without compromising bird welfare. Its robust design ensures minimal maintenance and resist corrosion — a common issue in humid tropical climates.

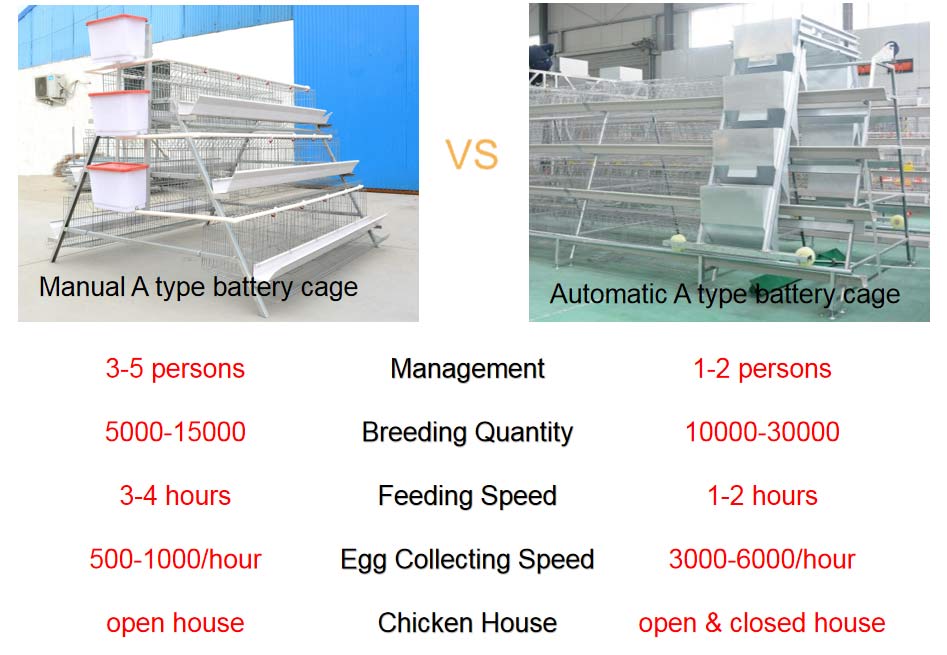

One of the most transformative aspects of this cage system is its integrated automation, which includes automated feed delivery and manure removal systems. The automatic feeding mechanism reduces labor dependency while ensuring consistent nutrition supply, critical for maximizing egg production.

The automatic manure removal system not only maintains hygiene but also significantly lowers health risks to the flock, enabling better growth rates and stability in egg-laying performance. In peak production periods, farms using this system have reported egg-laying rates surpassing 90%, a remarkable improvement from the average 70-75% typical in manual setups.

The performance of Zhengzhou Livi's cages is evidenced by extensive use in various countries across Africa, including Nigeria, where numerous commercial poultry operations have adopted these systems and reported sustained cost reductions and improved yields.

Specifically, a small poultry farm in Tanzania that integrated the A-Type Layer Battery Cage reported a 30% decrease in operational costs within their first production cycle while achieving a significant rise in egg production, positioning the farm on a path to sustainable development and scaling capacity.

Given its proven durability, scalable design, and automation efficiencies, the A-Type Layer Battery Cage makes an investment that directly addresses cost concerns and productivity goals in poultry farming. Its adaptability to diverse farm sizes and climatic conditions ensures it is a versatile asset for industry growth.

For global poultry farm operators and procurement specialists hunting for reliable, affordable, and advanced equipment solutions, Zhengzhou Livi Machinery Manufacturing’s offerings represent a trusted pathway to enhanced operational excellence.