As a commercial farm manager, you're always on the lookout for ways to maximize efficiency and productivity. One of the key decisions you'll make is choosing the right type of laying hen cages. H-type laying hen cages offer significant advantages over traditional flat cages, especially in terms of space utilization. In fact, they can save you over 30% of floor space compared to traditional flat cages.

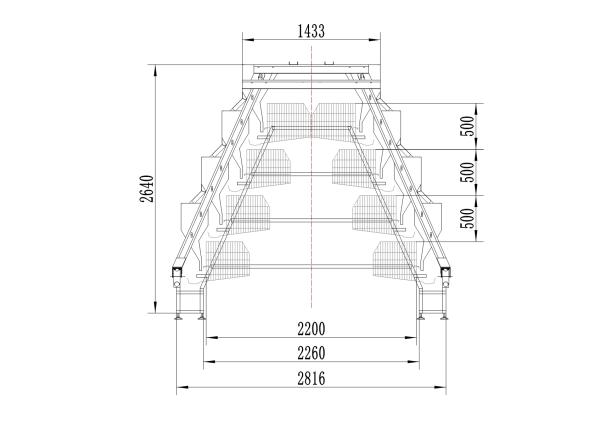

According to ISO 9001 and CE industry standards, H-type cages are designed to make the most of vertical space. This means you can house more hens in the same area, which is crucial for medium to large-scale commercial farms with chicken populations ranging from 5,000 to 30,000.

The H-type design allows for a more reasonable stocking density. With a proper layer configuration, hens have enough space to move around, which reduces stress and the incidence of diseases. For example, in a well-configured H-type cage system, the recommended stocking density can ensure that each hen has about 0.08 - 0.1 square meters of space, depending on the chicken breed and age.

Good ventilation is essential for the health of your flock. H-type cages are designed to promote better air circulation. The wind resistance coefficient of the H-type structure is optimized, which ensures that fresh air can reach every corner of the cage. Studies have shown that compared to traditional cages, H-type cages can improve ventilation efficiency by up to 20%, reducing the risk of respiratory diseases in hens.

Proper light distribution is also crucial for hen health and egg production. The unique structure of H-type cages allows for more uniform light distribution. This means that all hens receive an appropriate amount of light, which is beneficial for their biological rhythms and egg-laying performance.

| Flock Size | Recommended Layers | Modular Expansion Suggestions |

|---|---|---|

| 5,000 - 10,000 | 3 - 4 layers | You can add modules horizontally or vertically as your flock grows. For example, you can add a new cage unit every 6 - 12 months depending on your expansion plan. |

| 10,001 - 20,000 | 4 - 5 layers | Vertical expansion is more recommended at this stage. Make sure to check the load - bearing capacity of the cage structure regularly. You can add a new layer every 12 - 18 months. |

| 20,001 - 30,000 | 5 - 6 layers | When expanding to 6 layers, pay special attention to the overall stability of the cage system. It's advisable to consult a professional engineer. You can plan a large - scale expansion every 18 - 24 months. |

H-type laying hen cages are often equipped with advanced automation systems, including egg collection and manure cleaning systems. These systems can significantly reduce labor costs. For example, an automatic egg collection system can collect eggs efficiently, saving up to 50% of the labor time compared to manual collection. And the automatic manure cleaning system can keep the cages clean, reducing the risk of diseases and improving the overall living environment for hens.

These H-type cages are also very durable, with a service life of 15 - 20 years. This long - term durability means a lower replacement cost for you in the long run.

Many poultry behavior studies and actual farm cases have shown that the H-type design has a positive impact on egg production. The comfortable living environment, good ventilation, and proper light distribution all contribute to higher egg - laying rates. In some farms, after switching to H-type cages, the egg - laying rate has increased by 8 - 12%.

Ready to take your commercial poultry farm to the next level? Upgrade to our H-type laying hen cages and experience the benefits of efficient space utilization, improved flock health, and increased egg production. Click here to learn more!