In modern poultry farming, the durability of egg-laying cages significantly influences both operational stability and overall cost efficiency. Frequent equipment replacement not only disrupts production cycles but also adds unforeseen expense burdens, affecting profit margins. A cage system lasting beyond 15 years optimizes capital investment while ensuring minimal downtime. Selecting an appropriate corrosion protection method plays a vital role in achieving this longevity, especially in challenging farming environments where moisture, ammonia from manure, and mechanical wear accelerate corrosion.

Q235 steel is widely used in egg cage construction due to its cost-effectiveness, good mechanical properties, and availability. Its moderate carbon content (~0.2%) offers decent strength and weldability, making it ideal for structural frames. However, Q235 steel is inherently prone to surface corrosion if not adequately protected, especially in acidic and humid poultry house environments. Therefore, applying a reliable anti-corrosion coating is mandatory to prolong service life and maintain structural integrity.

| Surface Treatment | Typical Coating Thickness (μm) | Expected Corrosion Resistance (Years) | Key Benefits |

|---|---|---|---|

| Hot-Dip Galvanizing (HDG) | 70-100 | 15-20 | Thick zinc barrier, sacrificial protection, proven durability |

| Aluminum-Zinc Alloy Coating (55% Al, 43.5% Zn, 1.5% Si) | 20-25 | 10-15 | Superior heat resistance, slighter weight, better barrier under high temperature |

Hot-dip galvanizing provides a thick zinc coating that acts as both a physical barrier and a sacrificial anode protecting Q235 steel. The zinc layer’s typical thickness of 70-100 μm significantly delays penetration by corrosive agents such as moisture and ammonia—prevalent in poultry houses—to extend cage lifespan beyond 15 years. Furthermore, zinc hydroxides formed during corrosion can self-seal minor coating damages.

Conversely, aluminum-zinc alloy coatings create a thinner (~20-25 μm) yet thermally stable layer favored for high-heat applications. The aluminum-rich patina formed provides excellent heat and oxidation resistance but may exhibit marginally less durability when exposed to persistent acidic ammonia conditions and mechanical abrasion typical of chicken manure environments.

In humid or highly acidic manure-rich environments, HDG outperforms due to its sacrificial protection mechanism. For drier or temperature-variable climates, aluminum-zinc coatings offer benefits by mitigating thermal fatigue cracking and weight reduction. Ultimately, the choice must balance environmental stressors, expected equipment lifecycle, and maintenance capacity.

Regardless of chosen coating, routine inspection and upkeep are indispensable to safeguard cage integrity.

Key maintenance practices include:

Adhering to these simple yet effective operational steps can extend equipment functional life by several years beyond the protective coating’s baseline duration.

One commercial egg farm in coastal southern China reported over 20 years of operation using hot-dip galvanized Q235 steel cages combined with a quarterly maintenance regimen. This outperformed farms using aluminum-zinc alloy-coated cages exposed to similar salt-laden humid air where noticeable early rusting occurred around weak points within 10-12 years.

ISO 14713 standards highlight that galvanized coatings provide a minimum of 150 microns of combined zinc layer protection for structural steel exposed outdoors, aligning with observed field performance in intensive poultry farming applications.

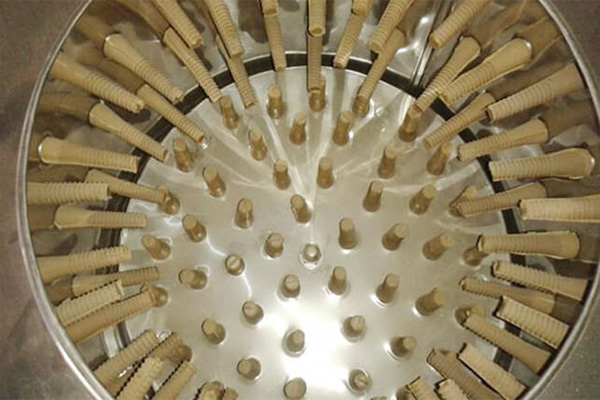

Discover the technical advantages of H-shaped Layer Egg Cage Design and Coating Solutions—engineered for longevity and operational savings.