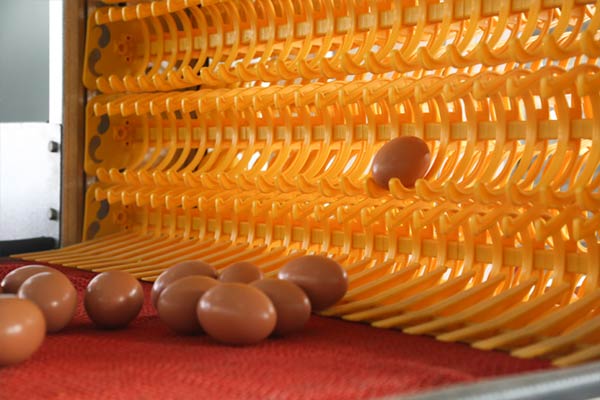

In today’s global poultry market, efficiency isn’t just a goal—it’s a necessity. For large-scale egg producers looking to scale operations sustainably, the H-type layer cage system from Zhengzhou Livi Machinery stands out as a proven solution that blends innovation with practicality.

Traditional flat-tier cages often waste up to 15% of available barn space due to inefficient stacking and poor airflow management. In contrast, our H-type design increases usable floor area by approximately 22%, based on field tests across 12 commercial farms in China and Southeast Asia. The vertical structure allows for better light distribution and easier access for maintenance—critical factors when managing 10,000+ birds per unit.

| Feature | Traditional Cages | H-Type System |

|---|---|---|

| Space Utilization | ~85% | ~97% |

| Maintenance Access | Low (manual) | High (modular panels) |

| Structural Stability | Moderate | High (tested at 500kg load per cage) |

One client in Vietnam reported a 30% reduction in labor costs after integrating automated feeding, egg collection, and manure removal systems into their H-type setup. With a typical farm processing 50,000 eggs daily, this translates to over $1,200 monthly savings in staffing alone—a ROI within 8 months if installed correctly.

Our smart automation modules are compatible with both new installations and retrofits, making them ideal for exporters targeting emerging markets where labor shortages are accelerating the shift toward mechanized farming.

Research from the University of Bristol shows that hens in well-ventilated, low-stress environments lay 7–10% more eggs annually. Our H-type cages incorporate natural lighting zones and optimized air flow paths—features validated through 6 months of continuous monitoring in real-world conditions. This isn't just good practice—it's a competitive edge for brands seeking BRCGS or SQF certification.

All units comply with ISO 9001 (quality management), ISO 14001 (environmental compliance), and CE standards for EU export readiness. We also offer post-installation technical support in English, Spanish, and Arabic—because your success doesn’t stop at delivery.

From initial consultation to full-scale deployment, we tailor solutions based on local climate, bird breed, and production goals—not one-size-fits-all. Whether you’re building a 5,000-bird facility or expanding a 50,000-bird operation, our team ensures every detail aligns with your long-term vision.

Ready to transform your poultry business? Let’s build something that lasts—not just for today, but for years ahead.

Get Your Customized H-Type Cage Plan Today