Tanzania’s small-scale poultry farmers often struggle to maintain sustainable operations due to several key challenges: fluctuating egg production rates, rising labor and feeding costs, and infrastructure limitations. These issues can stunt growth ambitions and threaten profitability in an increasingly competitive market.

However, innovation in poultry equipment has provided a turning point. Introducing the high-efficiency A-Type layer battery cage, crafted by Zhengzhou Livi Machinery Manufacturing Co., Tanzanian farmers are witnessing a transformation in their egg production and operational efficiency.

Constructed using hot-dip galvanized Q235 steel, these cages boast superior corrosion resistance critical in humid tropical climates. This robust material ensures a lifespan of 15 to 20 years, significantly extending replacement cycles and lowering long-term investment costs for farmers.

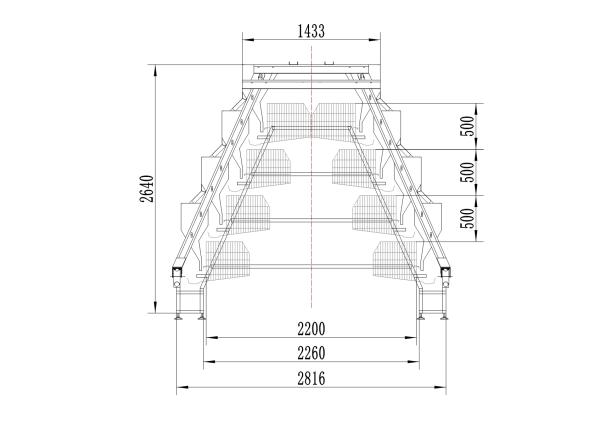

Farmers can choose from 3 to 5-tier configurations, with customizable capacities tailored to specific flock sizes. This flexibility enables scalable expansion without compromising chicken wellbeing or production efficacy.

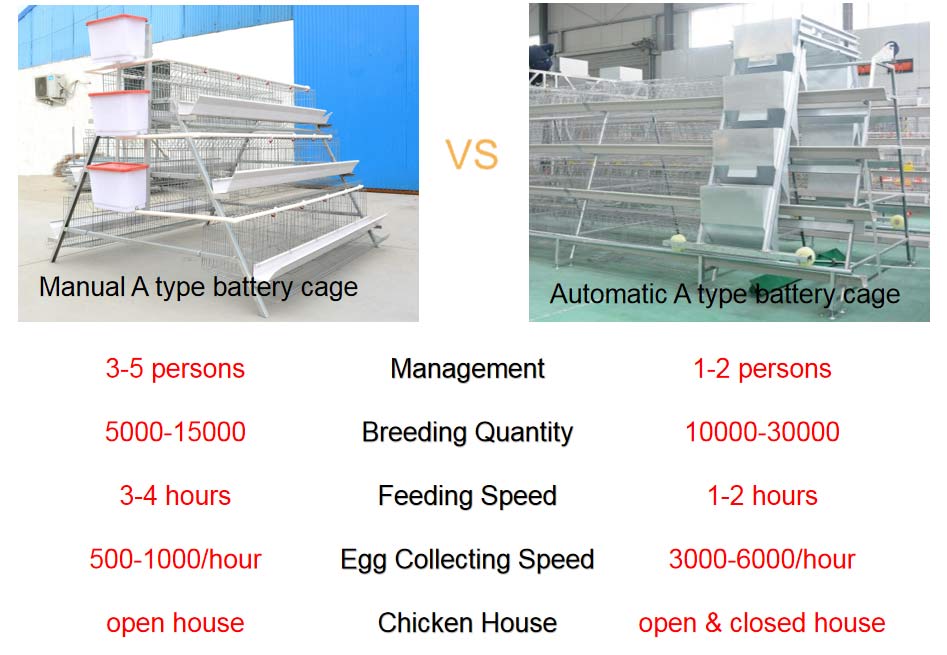

The A-Type layer battery cage integrates automated feeding and watering systems, reducing labor demands and limiting feed wastage. For example, the chicken drinking system keeps water fresh and accessible while minimizing spillage, ensuring optimal hydration, which is a key factor in consistent egg production.

By leveraging automation, the equipment significantly cuts down on manual work, allowing farm operators to focus on management and expansion. This modern approach has helped farmers reduce operational costs by approximately 20-30%, while simultaneously improving output.

Studies show that during peak laying periods, farms utilizing this cage design have achieved egg production rates exceeding 90%. This remarkable productivity is attributed to optimized space utilization and the ergonomic environment the cage provides, promoting better health and laying performance of hens.

A small Tanzanian poultry farm, previously challenged by high mortality rates and inconsistent egg yields, adopted the Zhengzhou Livi high-efficiency A-Type battery cage. Within the first year, the farm reported a sustained increase in egg output of nearly 35%, alongside a notable reduction in feeding and labor costs. This positive turnaround not only stabilized their revenue but also paved the way for expansion plans.

The farm's success story has attracted attention from neighboring regions, proving that high-quality poultry infrastructure is a cornerstone of sustainable agricultural development in emerging markets.

Besides Tanzania, this advanced battery cage system has been widely adopted across various countries in Africa, Asia, and South America. Its proven durability and productivity have won accolades at multiple international agricultural exhibitions. Buyers consistently praise its modular design, ease of maintenance, and adaptability to diverse climatic and operational conditions.

For global procurement managers and farm owners eager to enhance their poultry operations sustainably, this cage system presents a reliable solution that delivers measurable outcomes.

Ready to elevate your egg production and operational efficiency? Contact Zhengzhou Livi Machinery Manufacturing today to explore customized A-Type layer battery cages designed to meet your farm’s unique needs and ensure sustainable growth. Request a consultation or product brochure now!