Ghana’s poultry industry has long faced challenges in boosting egg production while maintaining high-quality standards. Limited infrastructure, suboptimal equipment, and fluctuating environmental conditions often hinder farmers from achieving consistent results. Addressing these difficulties, one leading Ghanaian poultry farm recently integrated advanced A-type layer chicken battery cages supplied by Zhengzhou Livi Machinery Manufacturing, marking a significant milestone in their operations and setting new benchmarks in egg quality and productivity.

The newly introduced cages are crafted from premium hot-dip galvanized Q235 steel, renowned for its exceptional rust resistance and durability under tropical conditions frequently encountered in Ghana. This material's robustness ensures extended service life and minimal maintenance, vital for reducing operational downtime.

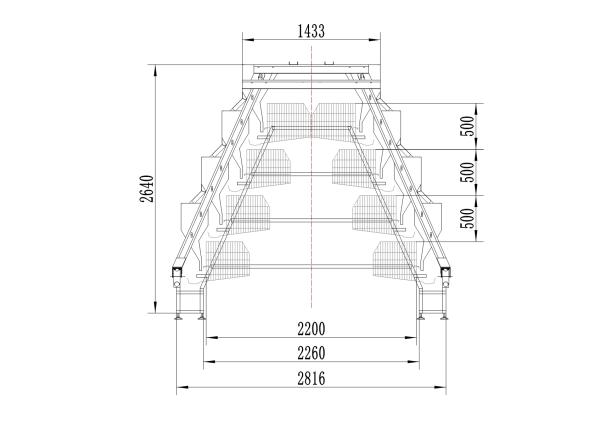

Designed with versatility in mind, the cages offer configurations ranging from three to five tiers, customizable to match the farm’s spatial constraints and flock size. Additionally, bespoke dimension adaptations cater to specific breeder requirements, enhancing flock comfort and operational efficiency.

State-of-the-art automation is embedded within these cages, including automatic manure removal systems, optimized feeding lines, and efficient watering mechanisms. Such automation fosters a healthier, stress-free environment for the layers, directly contributing to elevated egg production rates and superior egg quality.

Since the deployment of A-type layer cages, the Ghana poultry farm observed a peak egg production rate exceeding 90% during high-demand seasons, a remarkable improvement over previous cage systems averaging around 75-80%. This surge is attributed to the cage’s design minimizing layer stress and enhancing feeding efficiency.

Not only did quantity improve, but egg quality received a substantial boost. Parameters such as shell thickness, egg weight uniformity, and yolk color showed measurable enhancements validated by independent lab testing. Poultry experts highlight that these improvements contribute decisively to better market acceptance and consumer trust.

The farm’s reputation in regional markets soared following the improvement in both yield and egg consistency. Feedback from buyers emphasized the reliability of egg supply and superior freshness, which enabled the farm to negotiate advantageous supply contracts.

Moreover, the automated features significantly decreased manual labor needs by 30%, thus lowering operational costs and minimizing human error. This helped the farm optimize resource allocation while ensuring sustainable growth.

The successful adoption of these cages showcases the product’s ability to transform traditional poultry farming into modern, high-efficiency operations adaptable in developing markets like Ghana.

For poultry enterprises aiming to elevate egg production and improve egg quality sustainably, investing in high-quality equipment like the A-type layer chicken battery cages from Zhengzhou Livi Machinery Manufacturing proves invaluable. Its durable materials, customizable design, and automation features collectively advance farm efficiency, reduce costs, and enhance product marketability.

As demonstrated by the Ghana poultry farm’s success story, leveraging such innovative technology is a strategic step toward securing competitive advantage and long-term profitability.

Explore how our high-efficiency A-type layer chicken battery cages can transform your egg production and boost farm profitability. Contact Zhengzhou Livi Machinery Manufacturing today for detailed information, personalized solutions, and competitive quotations.

Request a Quote Now