In modern commercial egg production, maximizing space efficiency while optimizing hen welfare and operational costs remains paramount. Zhengzhou Liwei Machinery’s innovative H-shaped layer hen cage system addresses these challenges by revolutionizing the structural design of traditional poultry cages and embedding smart automation for enhanced management. This article explores how the H-shaped cage structure boosts space utilization, ensures stable construction, improves environmental quality, and lowers labor expenses—critical factors for managers overseeing medium to large-scale poultry farms.

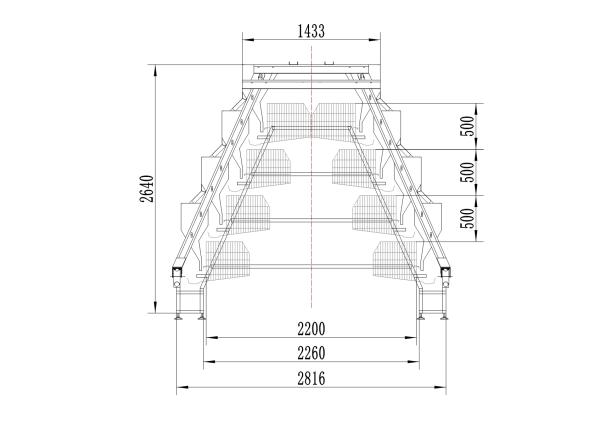

The defining characteristic of the H-shaped cage system lies in its distinctive multi-tiered framework with reinforced cross braces, forming an "H" footprint when viewed from the front or side. This geometry provides superior rigidity compared to traditional parallel or vertical-tiered cages, enabling greater vertical stacking while maintaining structural integrity.

This design directly translates into approximately 20-25% increase in usable floor space—a vital metric for facilities aiming to scale productivity without expanding their physical footprint. Unlike conventional cages which tend to have uneven load distribution causing deformation over time, the H-shape disperses force more evenly. This results in reduced maintenance downtime and longer system lifespan, contributing to overall cost savings.

Space Utilization Comparison

| Parameter | Traditional Cage | H-Shaped Cage |

|---|---|---|

| Vertical Space Utilization (%) | 70% | 90% |

| Structural Stability (Load Distribution) | Moderate | High |

| Maintenance Frequency (per year) | 3-4 times | 1-2 times |

Labor shortage and rising wage costs pressurize egg producers to automate the husbandry process. Zhengzhou Liwei's H-shaped cages seamlessly integrate automated feeding, watering, egg collection, and manure disposal systems. Such automation reduces manual interventions by up to 60%, allowing farm operators to reallocate labor to value-added tasks.

The intelligent design also features modular expansions for growing farm needs and real-time system diagnostics to preempt failures. This not only minimizes downtime but also improves consistent hen care quality, directly correlating with higher egg output rates.

The H-shaped configuration enhances airflow dynamics and natural light penetration within the poultry house. Ventilation channels incorporated into the structure prevent heat accumulation and ammonia build-up, creating healthier living conditions that reduce stress-induced laying dropouts. Objective studies show that adequate airflow can improve egg production by 5-10% while significantly lowering respiratory diseases.

Meanwhile, optimal lighting simulation through the cage's geometry encourages natural circadian rhythms in hens, fostering better feed conversion ratios and more consistent egg-laying cycles.

A commercial poultry farm in Henan province upgraded from traditional tiered cages to Zhengzhou Liwei’s H-shaped systems in early 2023. After six months of operation, key performance indicators showed:

These results not only improved profitability but also demonstrated sustainable animal management practices aligned with modern welfare standards.

To fully leverage the H-shaped cage advantages, farms should:

Choosing Zhengzhou Liwei Machinery’s H-shaped layer hen cages unlocks maximal operational efficiency, supporting scale and sustainability goals for next-generation poultry farming.

Explore How the H-Shape Can Transform Your Egg Production Facility

Discover Zhengzhou Liwei’s H-Shaped Cage Solutions for Maximum Poultry Farming Efficiency