Poultry farmers in Ghana are continually seeking innovative solutions to overcome challenges such as limited space, suboptimal egg production rates, and soaring operational costs. The imperative to improve yield while maintaining high-quality eggs and animal welfare standards drives the adoption of modern technologies. One standout solution making a significant impact is the A-Type Layer Battery Cage developed by Zhengzhou Livi Machinery Manufacturing. Its design and engineering address critical pain points, unlocking a pathway to higher efficiency and profitable growth.

Faced with fluctuating egg prices and escalating feed costs, Ghanaian poultry operations needed a system that would streamline management and accelerate production without compromising animal health. Traditional cage systems often suffered from poor durability and inadequate ventilation, leading to reduced egg yields and increased mortality rates.

Seeking to upscale a 50,000-layer chicken farm, a notable Ghana poultry operator partnered with Zhengzhou Livi Machinery Manufacturing to install their advanced A-Type Layer Chicken Battery Cage. This move promised a robust, scalable infrastructure equipped with the latest technological features.

The cages are fabricated from premium hot-dip galvanized Q235 steel, renowned for its exceptional sturdiness and corrosion resistance—key properties for longevity in the humid and harsh environments typical of poultry houses. The galvanization process enhances durability, effectively reducing maintenance costs over the years.

Available in 3 to 5 tiers, the configures can be tailored to farm size and space constraints. This modular approach enables gradual scaling, allowing operators to add layers according to production goals and budget. Customized features, such as feeding troughs and manure belts adapted to local needs, make this cage system uniquely flexible.

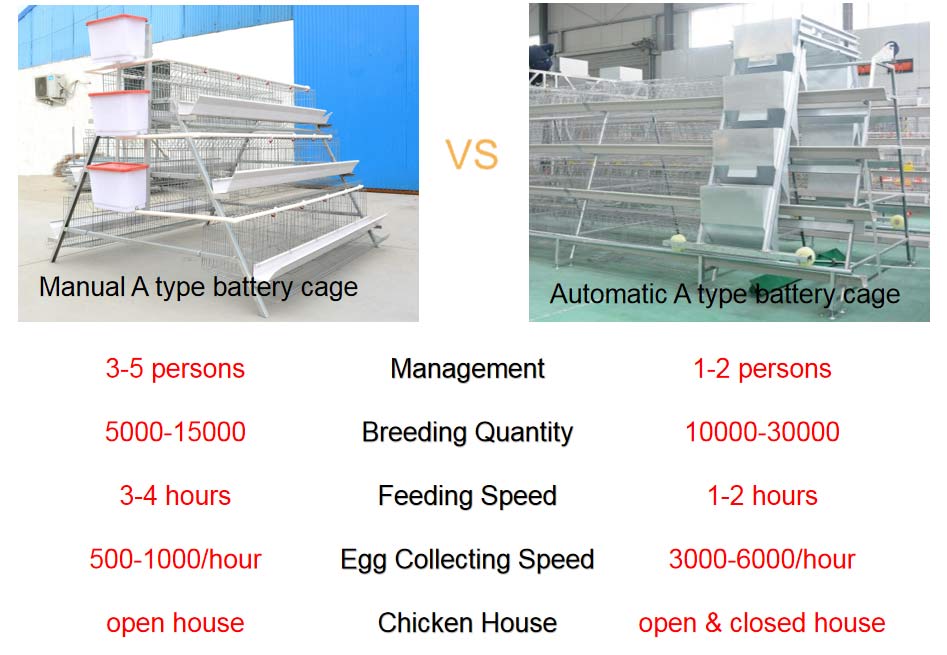

One of the standout advantages of Livi's A-Type battery cage is the seamless incorporation of automated functionalities. These include automated feeding, egg collection, and waste removal systems, which significantly reduce labor input and minimize human error.

Data collected from the Ghana poultry farm revealed a striking performance leap — the peak egg-laying rate surpassed 90%. This is attributed to optimized living conditions, stress reduction, and timely nutrition enabled by the cage’s design and automation.

After full implementation, the Ghanaian chicken farm experienced not only quantitative gains but qualitative improvements. Egg quality became more consistent, boosting market reputation and attracting premium buyers. Customer testimonials highlighted the ease of management and reduced labor fatigue, praising the cage system as “a game changer” for their operations.

Beyond immediate production benefits, the sustainability aspect resonates with environmentally conscious buyers, as automated waste removal lessens odor and contamination risks. These advantages collectively forge a competitive edge in a crowded marketplace.

The A-Type Layer Battery Cage from Zhengzhou Livi Machinery Manufacturing proves to be a vital asset for poultry producers aiming to elevate production efficiency while ensuring the welfare of their flocks. The combination of durable materials, configurable multi-tier design, and integrated automation offers a holistic approach to modern poultry farming challenges.

For poultry farmers seeking a trustworthy partner to enhance their egg production capabilities with proven, high-performance equipment, exploring this solution is highly recommended.