In the context of large - scale layer farming, the high cost of labor has become a significant pain point for farmers. According to industry statistics, labor costs can account for up to 20 - 30% of the total cost in traditional layer farms. This high - cost situation forces farmers to seek solutions to reduce labor input and improve efficiency. Therefore, the introduction of automated systems has become an inevitable choice.

Manual egg collection and manure cleaning are time - consuming and labor - intensive tasks in layer farming. In a traditional farm with 10,000 laying hens, it may require 5 - 6 workers to complete daily egg collection and manure cleaning. However, with the continuous increase in labor costs, this traditional labor - intensive model is becoming less and less sustainable. Automated systems, such as the automatic egg collection and manure cleaning systems, can effectively solve these problems.

The automatic egg collection system in the H - type layer chicken cage works by using a conveyor belt to collect eggs from each cage and transport them to a central collection point. This system reduces the risk of egg breakage and significantly improves the efficiency of egg collection. When selecting an automatic egg collection system, factors such as the speed of the conveyor belt, the accuracy of egg collection, and the durability of the equipment should be considered.

The manure cleaning system is another key part of the automated system. It uses a scraper or a conveyor to remove manure from the cages in a timely manner, which can keep the cages clean and reduce the incidence of diseases. When choosing a manure cleaning system, the cleaning efficiency, the ability to handle different types of manure, and the energy consumption of the system should be taken into account.

The H - type design of the layer chicken cage can make full use of vertical space. Compared with traditional cage designs, the H - type cage can increase the space utilization rate by 20 - 30%. This design not only allows more chickens to be raised in the same area but also simplifies the daily operation process. For example, the centralized layout of the cages makes it easier for farmers to feed, water, and inspect the chickens.

Let's take a real - world farm as an example. A large - scale layer farm in Zhengzhou introduced the H - type layer chicken cage with an automatic egg collection and manure cleaning system. After the transformation, the labor cost was reduced by more than 30%. The farm only needed 2 - 3 workers to complete the original work of 5 - 6 workers. At the same time, the egg production rate increased by 10 - 15%, and the health of the chicken flock also improved significantly.

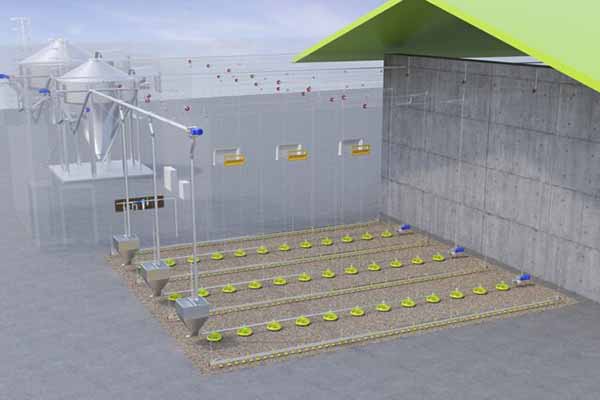

When installing the H - type layer chicken cage, it is necessary to ensure that the cages are evenly distributed in the chicken house to ensure good ventilation and lighting. The layout of the automatic egg collection and manure cleaning systems should also be coordinated to ensure the normal operation of the equipment.

For operation and maintenance, regular inspection and maintenance of the equipment are required. For example, the conveyor belts of the automatic egg collection system should be checked for wear and tear, and the scrapers of the manure cleaning system should be cleaned regularly to ensure their normal operation.

If you are interested in learning more about the application of H - type layer chicken cages in modern layer farms and want to get practical tools such as free plan templates and video tutorials, click here to obtain them. Let your farm become more intelligent and worry - free!