In the realm of large - scale poultry farming, the traditional method of manual egg collection has long been a headache for farmers. It is time - consuming and labor - intensive, often requiring several workers to spend hours each day collecting eggs. Moreover, the high breakage rate is a persistent problem. On average, the breakage rate of manual egg collection can reach up to 5%, which not only causes direct economic losses but also affects the overall quality and marketability of the eggs.

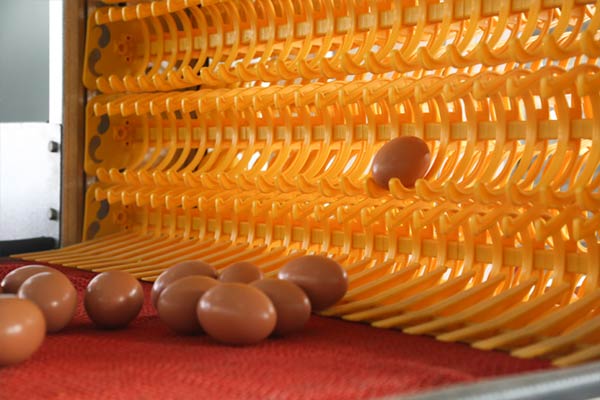

Automated egg collection systems offer a revolutionary solution to these problems. There are two main types: the roller - type and the conveyor - belt type. The roller - type egg collection device operates on a simple yet effective principle. Eggs roll along a series of rollers, which gently guide them towards a collection point. This system is highly integrated with the egg - laying cages, allowing for a seamless transfer of eggs. The conveyor - belt type, on the other hand, uses a continuous belt to transport eggs from the cages to the collection area. It can be easily adjusted to fit different cage layouts and sizes.

Let's take a look at a real - life case. A large - scale farm with ten thousand laying hens implemented an automated egg collection system. Before the upgrade, the daily egg collection process took about 5 hours and had a breakage rate of around 5%. After the installation of the automated system, the daily egg collection time was reduced by 40%, down to just 3 hours, and the breakage rate dropped significantly to 1.2%.

When comparing the two types of automated systems, several key indicators need to be considered. In terms of egg collection speed, the conveyor - belt type is generally faster, capable of collecting eggs at a rate of up to 10,000 eggs per hour, while the roller - type system can handle around 8,000 eggs per hour. However, the roller - type system has a lower failure rate, usually less than 5% compared to the conveyor - belt type's 8%. In terms of cleaning convenience, the roller - type system is easier to clean as it has fewer complex parts. And in terms of labor cost, both systems can significantly reduce the need for manual labor, with the conveyor - belt type potentially saving more in large - scale operations.

| Indicator | Roller - type | Conveyor - belt type |

|---|---|---|

| Egg collection speed | 8,000 eggs per hour | 10,000 eggs per hour |

| Failure rate | Less than 5% | 8% |

| Cleaning convenience | High | Medium |

| Labor cost savings | Significant | More significant in large - scale |

During the operation of the automated egg collection system, some common problems may occur. For example, egg jams, motor malfunctions, and loose chains are relatively common. Regular maintenance and timely troubleshooting can effectively solve these problems. We have also prepared a set of practical pre - installation evaluation checklists, which include aspects such as chicken coop size, power supply configuration, and staff training. You can download the PDF version of this checklist to ensure a smooth installation process.

It's worth noting that our automated egg collection systems are compliant with ISO and CE certifications, ensuring high - quality and reliable performance. With a service life of 15 - 20 years, they can bring stable long - term benefits to your farm.

"Since we installed the automated egg collection system, our farm has become much more efficient. The daily operations are now much easier, and the quality of our eggs has also improved significantly." - A satisfied customer

If you are considering upgrading your farm to an automated egg collection system, now is the time. Immediately consult Livi's mechanical technology advisors to get a customized automation transformation plan for your farm.