Livi Machinery's A-type layer battery cage is at the forefront of the automated egg - laying chicken farming industry. This high - performance system boasts a series of advanced features that set it apart from traditional cages. For example, the cage is designed with optimal space utilization in mind, allowing up to 10 chickens per square meter, a 20% increase in density compared to standard cages. The material used in the cage is a high - strength alloy, which not only ensures the safety and comfort of the chickens but also has a long service life, reducing the need for frequent replacements.

The automated feeding system of Livi Machinery is based on a precise control mechanism. It can distribute the right amount of feed to each cage according to the growth stage and nutritional needs of the chickens. For instance, in a large - scale farm with 10,000 chickens, the automated feeding system can save up to 3 hours of labor per day compared to manual feeding. The system calculates the feed quantity based on the number of chickens in each cage and the pre - set feeding schedule.

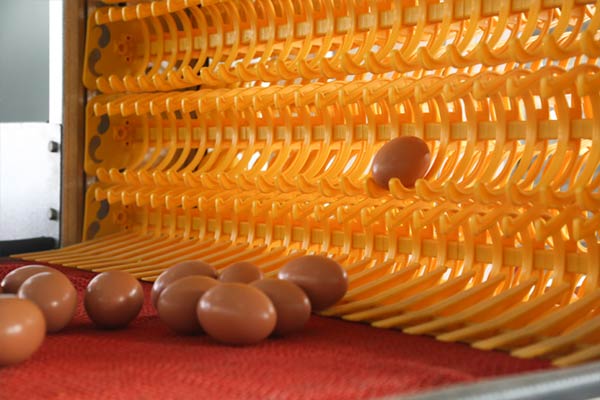

The feces cleaning system is another highlight. It uses a conveyor belt system that continuously removes feces from the cages. This not only keeps the cages clean but also reduces the risk of disease transmission. The conveyor belt moves at a speed of 10 centimeters per minute, ensuring that feces are removed in a timely manner. The egg collection system is equally efficient. It uses a gentle rolling mechanism to collect eggs without damage. In a test farm, the egg breakage rate was reduced from 3% to less than 1% after using this system.

In Nigeria, a medium - sized farm with 5,000 chickens adopted Livi Machinery's automated system. Before the adoption, the farm had an average daily egg production of 3,500 eggs with a labor cost of $200 per day. After using the system for six months, the daily egg production increased to 4,200 eggs, a 20% increase, and the labor cost was reduced to $120 per day, a 40% reduction.

In Kenya, a large - scale farm with 20,000 chickens saw even more significant results. The egg production increased from 15,000 eggs per day to 18,000 eggs per day, a 20% growth, and the labor cost was cut by 45% from $800 per day to $440 per day. A table below summarizes these data:

| Country | Number of Chickens | Pre - adoption Egg Production | Post - adoption Egg Production | Pre - adoption Labor Cost | Post - adoption Labor Cost |

|---|---|---|---|---|---|

| Nigeria | 5,000 | 3,500 eggs/day | 4,200 eggs/day | $200/day | $120/day |

| Kenya | 20,000 | 15,000 eggs/day | 18,000 eggs/day | $800/day | $440/day |

Automated farming with Livi Machinery's systems significantly enhances production efficiency. By reducing the time and effort spent on manual tasks, farmers can focus on more strategic aspects of the farm, such as disease prevention and market expansion. Moreover, the reduction in labor costs directly contributes to higher profit margins. For example, in the above - mentioned farms, the saved labor costs could be reinvested in improving the quality of feed or upgrading other farm facilities.

Livi Machinery understands that different farms have different needs. For small - scale farms with less than 1,000 chickens, it offers a basic automated package that includes a simple feeding and egg collection system. For medium - scale farms (1,000 - 10,000 chickens), a more comprehensive system with advanced feces cleaning and data monitoring functions is available. For large - scale farms with over 10,000 chickens, a fully integrated solution with real - time remote control and big - data analysis is provided.

The future of the egg - laying chicken farming industry lies in intelligent and sustainable development. Livi Machinery is committed to continuous innovation. In the future, its systems may be integrated with artificial intelligence to predict chicken health and egg production more accurately. The industry is also moving towards more environmentally friendly practices, and Livi Machinery is researching ways to reduce energy consumption and waste in its systems.

Don't miss out on the opportunity to transform your egg - laying chicken farm! Join the many successful farmers in Africa who have already benefited from Livi Machinery's automated systems. Click here to learn more and start your journey to a more efficient and profitable farm today!